Autumn 2015

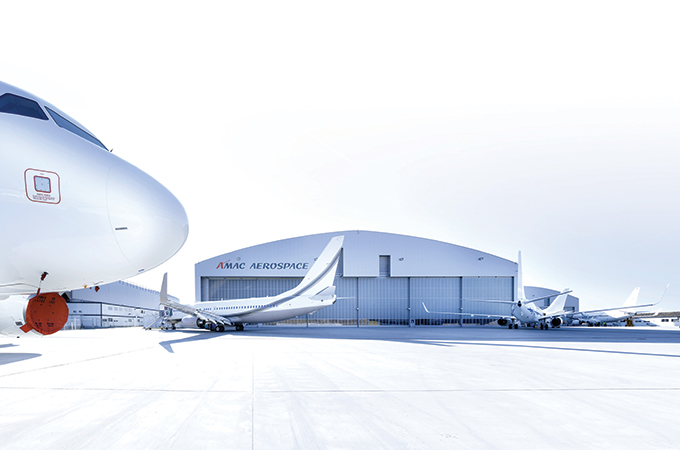

AMAC Aerospace’s Basel facility has undertaken a host of prestigious contracts as well as one for the record books

It’s been a sizzling summer season for AMAC Aerospace with the Swiss-based aircraft completions and maintenance specialist winning and executing a long list of prestigious orders that included aircraft for Heads of State and the world’s first VVIP B747-8 Intercontinental.

In July, AMAC Aerospace Switzerland revealed it had delivered its first B747-8i in a VVIP configuration, under a completions contract which took two years to execute.

This made AMAC Aerospace the first completions centre in the world to redeliver an aircraft of this size and complexity, according to the company.

Under the contract, the cabin was decorated with the highest levels of custom furniture, monuments, exotic materials, bespoke artwork, and easy flow of passenger mobility throughout the cabin, along with plenty of storage space and high-end technical equipment, such as peripheral cameras located around the exterior of the aircraft, Live TV, Satcom installations, additional water tanks, showers, beds, and galleys to name but a few.

“We were all proud to see this project come to an end; we hope that the principal will recognise the level of detail coming from our skilled craftsmen and women. We would like to thank our client, his flight operations team, and all the men and women that have made this project a reality,” says Christian Schirlin, Head of Project Management, AMAC Aerospace.

“The tireless efforts made by our teams of people working day and night are a testament to why we are the best in this business. We have really come a long way with this B747-8i as it has tested every person as an individual as well as challenged the departments who have relentlessly combed through thousands of documents, from production to analysis, to installation to certification through to the acceptance tests and shake-down flights. New learning curves have enabled AMAC to refine and better our products, procedures and have given valuable insights into what is feasible. We are extremely happy with the end result and we relish the opportunity to take on our next wide-body project,” says Bernd Schramm, Group Chief Operating Officer (COO), AMAC Aerospace.

The month of July also saw AMAC win a contract to refurbish a Boeing Business Jet (BBJ) 737-700, and a new heavy base maintenance contract for a Boeing 777-200, while successfully returning a BBJ3 737-900ER to service following an interior reconfiguration, in addition to completing a C-check on a VIP Airbus jet.

The BBJ 737-700 refurbishment contract was awarded to the AMAC’s facility in Basel by an undisclosed client. Under the contract, all cabin seats and divans will be stripped and reupholstered in accordance with the new approved design package and a new hand-made customised carpet will be installed in the cabin of the jet. All cabin work has been certified by AMAC’s in-house design department.

In addition to the refurbishment contract, AMAC Aerospace revealed it has returned the BBJ3 737-900ER to service following the interior reconfiguration, which included a built-up upholstery of new VIP seats, the installation of electrical high-low tables and a new VIP handmade carpet while the existing divans were modified to add more functionality and better comfort. The modification was accomplished on the EASA STC (European Aviation Safety Agency Supplemental Type Certificate). AMAC says the customer was “fully satisfied with the quality of workmanship and the on-time delivery of his BBJ3 737-900ER”.

For the C-check on an A330-200 VIP aircraft, various cabin interior details were reworked in accordance with the customer’s requirements for refurbishment. The C-check was performed to the customer’s total satisfaction and the aircraft was delivered a week before the contractual delivery date.

HEADS OF STATE

The month of August saw AMAC win two prestigious contracts involving aircraft for Heads of State while completing two other contracts to the satisfaction of their customers.

The first order was from an undisclosed Head of State for a base maintenance contract on a A319 VIP jet. Beside the heavy base maintenance, the Basel facility was contracted to work on several cabin rectifications such as replacing soft materials and refreshing the VIP seats to enhance the overall appearance of the aircraft in three week’s ground time.

The other contract signed was for base maintenance on a Global Express aircraft from an undisclosed Head-of-State customer. Under the contract, the aircraft would undergo a base maintenance inspection in combination with cabin modifications. Based on the customer’s request, the cabin modifications would be done by AMAC Aerospace in order to optimise the efficient use of space.

The jobs completed that month involved a C-check on an A319 aircraft and a STC (supplemental type certificate) level modification and heavy base maintenance on an A319 VIP jet.

The C-check was performed in a very challenging ground time to meet the customer’s requirements and expectations. Various cabin rectifications were carried out along with avionic cockpit upgrades. During the C-check, an upgrade of the Satcom system was performed to incorporate swift broadband capability to the cabin. The customer was quoted to be fully satisfied with the on-time delivery of his A319 and AMAC’s high quality of workmanship.

Meanwhile, the A319 VIP aircraft was successfully returned to service after the STC level modification and a heavy base maintenance project.

This major refurbishment and modification project included a customised VIP carpet replacement, a re-upholstery of all seats and divans and an installation of a new inflight entertainment system offering HD (high-definition) monitors as well as audio video on demand with wireless streaming to personal electronic devices.

A second stand-alone high-speed Satcom system was installed to offer passengers further connectivity. Due to the cabinet modifications, the customer was pleased to have received additional storage capacities and more space in the cabin during its operations, says AMAC.

The modification and refurbishment work was carried out in parallel with a heavy base maintenance project including landing gear overhauls. The cabin refurbishment was performed and certified on time during a very challenging ground time to meet the operational requirements as well as the customer’s expectations, it adds.

September saw AMAC successfully return to service an A320 aircraft, which was handed to AMAC by an undisclosed Head-of-State customer for a heavy base maintenance check, which also included a Satcom and a cabin connectivity upgrade for enabling the GSM (global system for mobile communications) usage on board.

The Basel facility also received two maintenance contracts for an A320 VVIP and A330-200 VIP jets.

The contract for the A320 VVIP aircraft involved a heavy base maintenance check including a landing gear overhaul, seat refurbishment and various cabin upgrades and modifications.

The contract for the A330-200 VIP aircraft meanwhile, involved performing several maintenance services on the jet.

“The undisclosed customer chose AMAC because of the huge expertise and the various in-house shop capabilities to work on a VIP cabin interior,” says an AMAC spokesman.

In its latest success, the completions specialist revealed it had delivered a BBJ after having performed cabin refurbishment and maintenance work.

The aircraft was sold to a new customer who selected AMAC to install a new design concept in the cabin by changing the colours and materials of the seats and divans. AMAC was chosen due to the short lead time and ground time required for this project.

The company provided complete and comprehensive support with regard to the pre-buy inspection, all rectification, refurbishment and maintenance work as well as the transfer of asset.

AMAC also provided assistance to enable a smooth transition to the customer’s newly appointed CAMO (Continuing Airworthiness Management Organisation).

AMAC Aerospace specialises in narrow and widebody VIP completions and maintenance for the corporate and private aviation market. Founded in 2007 in Basel, it today is the largest privately owned facility in the world and led by Kadri Muhiddin, Executive Chairman/Group Chief Executive Officer (CEO), Schramm and Mauro Grossi, Group CFO (Chief Financial Officer).

The company’s order book currently stands at around $1 billion.