Tue, Apr 5, 2016

Lufthansa Technik is showing off a new induction cooking platform - which opens up new opportunities for freshly prepared cuisine on board one’s private jet – at the 2016 Aircraft Interior Expo.

The two-day expo opens today in Hamburg, Germany, featuring 1,000 airline buyers and 530 leading aircraft interiors suppliers, and is expected to attract as many as 14,000 visitors.

Induction cooking is fast, clean, safe and efficient but also difficult in an aircraft. However, after conducting preliminary studies together with hs2 engineering, Lufthansa Technik has developed and filed a patent for a prototype of an induction cooking platform.

The induction cooking platform has made it onto the list of finalists for the coveted Crystal Cabin Award at the expo.

With dimensions of just 287 x 570 x 269 mm (ARINC Size 4) and weighing just 13.5 kg, it fits into any aircraft kitchen. It is being presented as an all-in-one solution, including power unit, exhaust fan and a special cover, which ensures that pots and pans remain in place even during turbulence.

“There are a number of applications which enable not only cooking with pots and pans, but also the use of a special rice cooker with different settings and a toaster,” explains Franziska Voerner, lead project manager for Original Equipment Innovation at Lufthansa Technik.

Talks are under way with potential customers, flight attendants and chefs to gauge market requirements and modify the solution to fit the exact needs of the users.

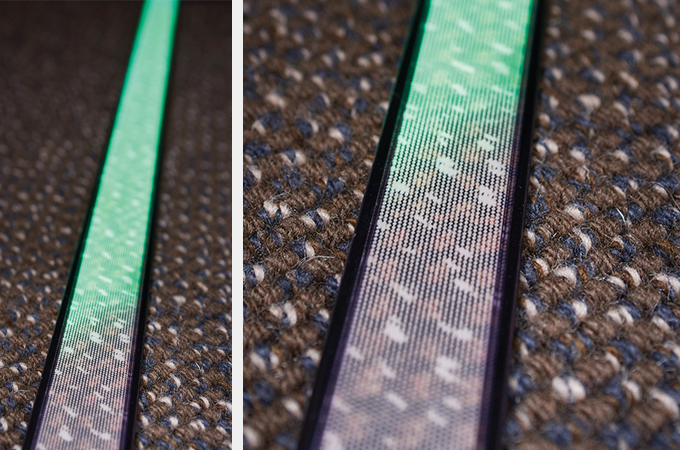

Lufthansa Technik is also showing off the latest version of its GuideU emergency floor path marking system – called GuideU CustomFit – which matches the interior carpet design on a jet.

Engineers have refined the GuideU system to be only visible when actually needed, and GuideU CustomFit can be fully integrated in any carpet and flooring design.

Torben Biehl, Head of product development for GuideU at Lufthansa Technik, explains: “With the ability to print each individual design directly in our luminous strips, we can now completely integrate emergency floor path marking in the overall design of the airline cabin. Only in the event of a lighting system outage do the markings appear clearly on the floor and guide the way to the closest exit. And as before, the system is totally maintenance-free.”

GuideU is billed as the world's flattest and lightest floor path marking system and the first non-electrical system that can be contoured into virtually any shape, benefiting aircraft manufacturers, customers and interior designers alike. GuideU absorbs light from the cabin and can show the way to the emergency exits for up to 22 hours without interruption after a brief "charging" period.

GuideU is available in many different colours. As customer options, an even flatter filler is available, which serves as an underlay and a special, flexible carpet protector for the carpet edges. The latter is also available in several colors and can be matched with the GuideU color range.

Other innovations on show include Lufthansa Technik’s flying DishwashAir, specially designed for use on board commercial aircraft.

Voerner and Biehl will both be at the Lufthansa Technik stand (Hall 6, Stand 6B80) at the Aircraft Interiors Expo.

WATER TRANSFER PRINTING

Meanwhile, Lufthansa Technik is currently in the process of putting into operation a completely new production system for the printing of aircraft interior panels and cabin elements.

The so-called water transfer printing process involves printing onto the cabin elements with a wafer-thin film. Once the print is varnished, the result is a customized design with an especially high-grade surface.

“We have used this technology for more than ten years to create the most discerning one-off products for equipping VIP jets and we have built up a great deal of know-how," says Thorsten Hagemann, Head of Aircraft Interior Production at the VIP & Special Mission Aircraft Services division at Lufthansa Technik. “Our new system is the largest of its kind. The automation of key process steps allows us to substantially shorten our lead times while maintaining an even higher standard of quality."

Whether the look is imitation wood with the finest grain, a carbon fibre or a stone optic, there are no limits to what can be imagined.

"With this system, developed especially for us, we can make a quantum leap in the visual design of aircraft cabins while maintaining a high level of production efficiency," says Hagemann.