Thu, Jan 14, 2016

AMAC Aerospace has opened its fourth hangar at EuroAirport in Basel, Switzerland, after only 11 months construction time.

The additional hangar area of 7,280 sq m and the additional apron area of 6,038 sq m will allow the VIP aircraft completions and maintenance specialist expand its capacity for wide-body maintenance work.

DEDICATED ROLE

The new hangar is designed to accommodate at least one wide-body aircraft and two narrow-bodies respectively. Unlike the already existing three hangars, the fourth one is purely dedicated to maintenance projects and wide-body aircraft. AMAC Aerospace dedicates one wide-body hangar to maintenance and two wide-body hangars to completions and refurbishment services. These hangars together comfortably accommodate multiple narrow- and wide-body aircraft, Boeing B747s, B777s, B787s, Airbus A340s, A330s and can extend to service an A380. AMAC`s smaller hangar is designed to simultaneously accommodate a wide variety of aircraft combinations for maintenance work. For instance, two narrow-body aircraft, Boeing Business Jets and/or Airbus A318, A319, A320, A321 or Gulfstreams and selected Bombardier jets.

“Our brand new fourth 7,280-sq-m hangar is our maintenance centre for privately-owned and operated wide-body aircraft, serving our clients from around the world. We are proud to offer our esteemed clientele the chance to experience AMAC professionalism in handling these specially conceived aircraft so notorious for demanding considerably more attention than standard airliners,” says Kadri Muhiddin, Group Executive Chairman and CEO of AMAC Aerospace.

HIGHEST STANDARDS

The construction of hangar number four was done in less than one year downtime. Around 60 workers have been occupied at its peak. The same construction team, architects and engineers that were involved in the construction of the other three hangars have again been part of the build-up of the new hangar. All hangars are equipped with the latest technological innovations. They meet the highest standards of safety and respect environmental materials in construction. AMAC Aerospace says it was very well supported by the local authorities throughout the planning phase and the construction of the fourth hangar.

SUCCESSFUL YEAR

The inauguration of the fourth hangar is just one highlight at the end of a very successful year at AMAC Aerospace. There have been several milestones achieved within the last 12 months, to name only a few:

• In June, AMAC Aerospace was successfully awarded the Federal Aviation Administration (FAA) Air Agency Certificate empowering it to operate an FAA-approved repair station. The long anticipated arrival came after several years of negotiations with its industry peers. AMAC Aerospace is now authorised to undertake repair station work on airframes, accessories, power plants, landing gears and non-destructive inspections, testing and processing on N registered aircraft.

• In July, AMAC Aerospace successfully completed and returned to service its first B747-8i in VVIP configuration, which stemmed over a two year project downtime. This made it the first completions centre in the world to redeliver an aircraft of this size and complexity.

• In August, a VVIP B777-200 aircraft was inducted for a heavy base maintenance check at Basel with various cabin system modifications and upgrades to be performed for enhanced passenger comfort. AMAC was chosen by the undisclosed customer due to its high level of expertise in removing and reinstalling VVIP cabin interiors.

• In November, Pilatus appointed Amac Aerospace as the exclusive sales distributor for its all-new PC-24 light jet in the Middle East, extending Amac’s existing agreement with the single-engine turboprop aircraft manufacturer as an authorised service centre and sales distributor for the PC-12NG in the region.

• A privately owned Airbus A319 has been inducted for a heavy maintenance C Check at Basel, and various modifications on the Satcom system as well as on the Passenger Information System (PIS) will be undertaken.

• A new heavy base maintenance contract was signed for a privately owned A330 with an undisclosed customer and the aircraft was inducted at the end of 2015.

• Most recently, a heavy base maintenance contract for a Head-of-State BBJ (737-700) has been signed. Various cockpit updates and cabin modifications will be performed during this layover and the aircraft will be inducted in the first quarter of 2016.

AMAC Aerospace Switzerland offers narrow- and wide-body VIP completions and maintenance for the corporate and private aviation market with its main facilities strategically stationed in the heart of Europe at EuroAirport Basel-Mulhouse.

Founded in 2007, the company has had extraordinary success over the last eight years and today is the largest privately owned facility of its kind in the world.

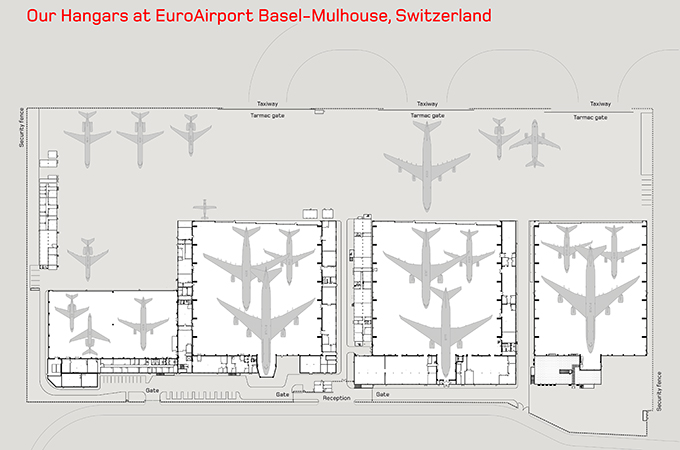

AMAC Aerospace operates four hangars with an expansion zone of 28,280 sq m floor space, 6,251 sq m of workshop and office space as well as an apron area of 44,610 sq m. The securely fenced tarmac opens directly onto the linkage taxiway. AMAC Aerospace runs now more than 85,000 sq m working space in total at EuroAirport.

To provide maintenance services for Middle Eastern clients’ PC-12 NGs, AMAC runs a state-of-the-art hangar at Istanbul’s Atatürk Airport in Turkey.